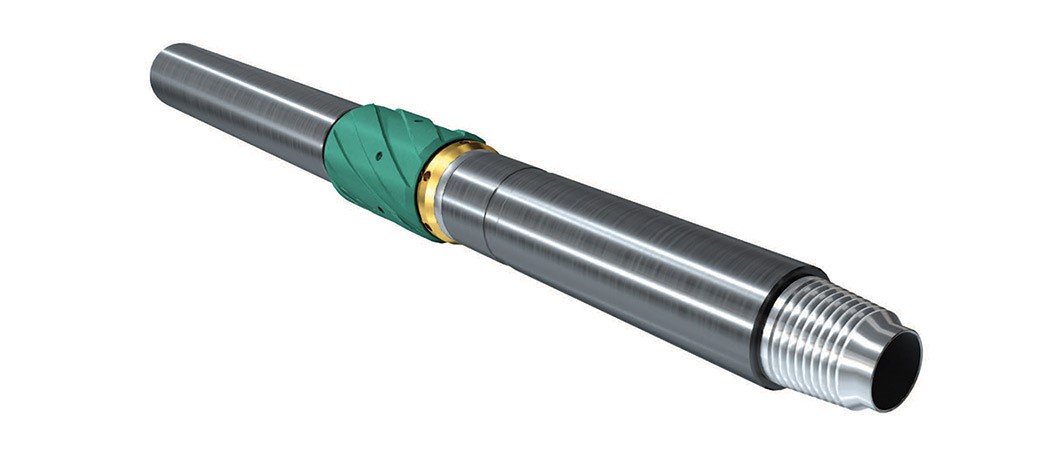

The VeRidrift™ Casing Drift is a robust, 360° free rotating contact, wellbore clean-up tool and can be run individually or modularly as part of the OWS ArmRdillo™ Wellbore Clean-Up System. The VeRidrift™ Casing Drift can be adapted to suit any casing size and drill pipe combination.

Features

- Fluted Centralizer Drift provides centralization, bypass while drifting the casing

- Free rotating tool design with Internal Bearing Rings to prevent drill pipe, tool or casing wear

- No external bolts, clamps or fasteners that can come loose down hole

- Robust assembly method with multiple back-ups

Benefits

- Cost savings

- Drift casing to ensure the completion can be deployed without hanging up, saving Non-Productive Time

- Integrity

- Ensures the casing conforms to the minimum drift requirements of API or special drift requirements of the operator

- Single piece mandrel with no internal connections for increased strength

- Reducing Non-Productive Time

- Assurance the completion packers and other components can be deployed safely

Applications

- Pre-completion wellbore clean-up operations to ensure the scraper, brushes and mills have removed any hardened cement

- Non-rotating stabilizer run above or below weight set tools to weight transmittal

- Drifting perforated sections prior to running lower completion screens and swellable packers

Operational

- The VeRidrift™ Casing Drift is typically run to ensure that the casing wall is free of cement sheath and other debris

- Cement plugs can be drilled inside the casing as required

- During displacement the drill string can be rotated and reciprocated to improve hole cleaning without fear of damage or wear of the casing, drill pipe or of the VeRidrift tool