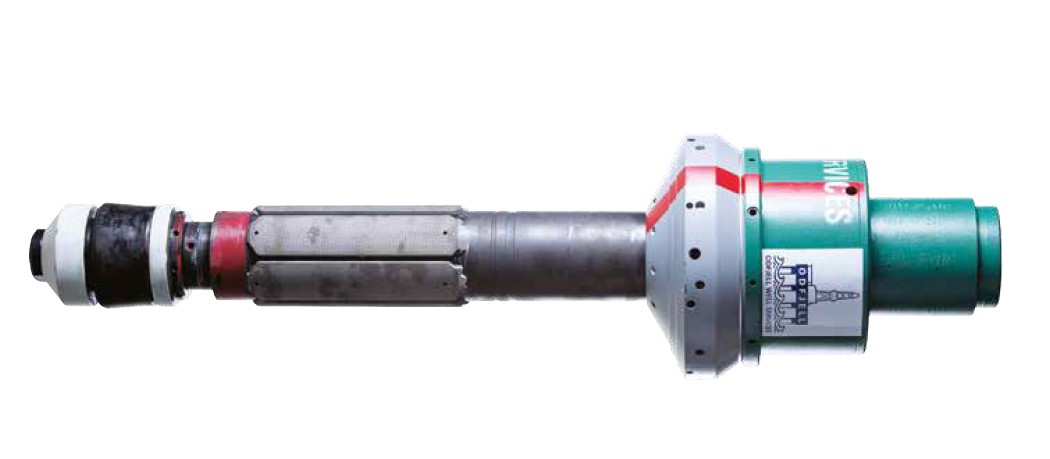

The OWS CRTi tools are designed for casing running or drilling with top drive equipped rigs to enable connection make-up, break-out, circulation and rotation, increasing the chance of getting casing to TD the first time. These tools are mechanically activated in tension and both rotational directions solely by top drive control using TAWG™ (Torque activated Wedge grip) technology.

This patent pending architecture puts control in the hands of the driller, increasing the success rate to get the casing installed the first time. Rig-in and rig-out steps are simple, intuitive and fast. This architecture has a proven track record in running over three million meters of casing.

How does the Casing Running Tool work?

Starting from the insertion diameter of the base tool, selectable sizes of integral jaw/dies are used to configure the CRTi tool to support gripping casing of increasing internal diameter (decreasing weight). Through the use of a patent pending extended reach die structure, the gripping diameter can be further increased to include casing sizes much greater than the base tool.