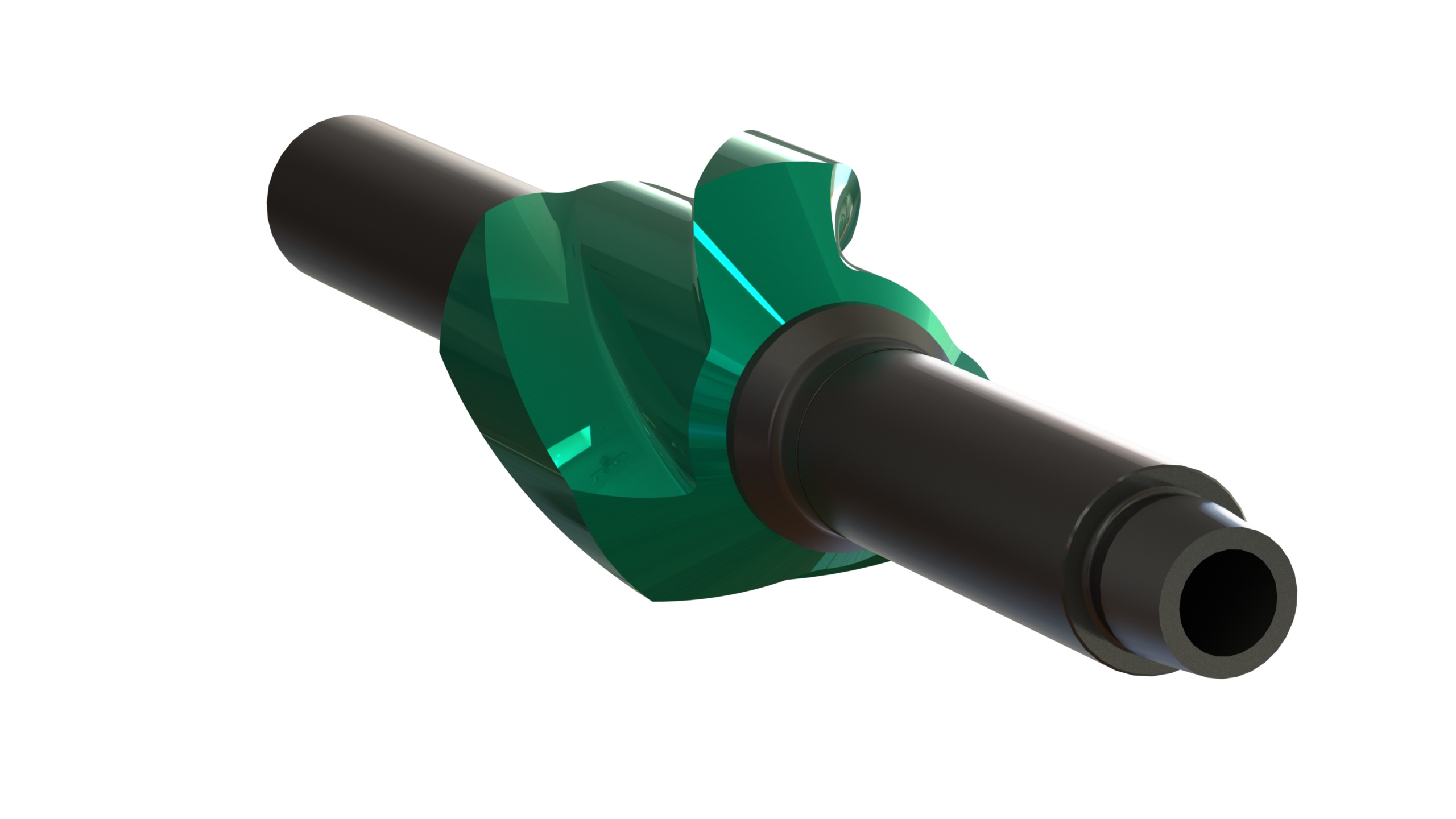

The RizeRdillo Advanced Jetting Riser Displacement Sub is an effective tool that opens communication ports between the drill pipe and the annulus. This allows for the cleaning of the Riser and BOPs. After cleaning, the ports can be closed again to reestablish communication with the drill bit.

Features

- Single-piece Mandrel with no internal connections.

- 16” OD Jetting Sleeve with 12 offset jetting ports for optimum jetting action.

- 12.750” OD Jetting Sleeve with 12 offset jetting ports for optimum jetting action.

- Simple drop ball(s) to shear mechanism with no reliance on darts etc.

- Tool can be dressed with various types of O-ring elastomers to suit variances in temperature, chemical resistance or pressures.

Benefits

- Cost-Savings

- Maximizing riser cleaning efficiency to reduce operating time has a huge impact on operating costs on expensive semi-submersibles

- No field maintenance required

- Integrity

- Available with high torque connections reducing the

- need for reduced strength crossovers

- Single piece mandrel with no internal connections for increased strength

- Reducing Non-Productive Time

- Reduces premature failure of completion equipment by debris which can interfere or damage valves, electronics and other hardware

Applications

- Cleaning Risers, BOPs, Wellhead Area

- Pumping cement or executing a displacement through the tool to TD

Operational

- With the offset nozzle arrangement, you can achieve 360-degree coverage without the need for rotation.

- The tool can be utilised with the RizeRdillo Riser Cleaning Tool, MalstromXT Wellhead & BOP Jetting Tool and BOP Junk XTractR to fully optimise Riser /BOP cleaning operations.

- To allow fluid to flow into the annulus, a ball is dropped to open the tool flow ports when needed. To resume circulation through the whole drill string, a second ball can be dropped to close the ports, completing one full opening and closing cycle.