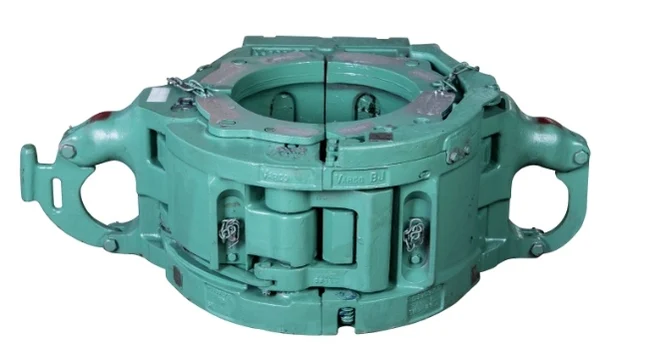

What is a BX elevator?

The BX elevator is a hydraulic, remotely operated elevator, with changeable bushings, to easily change the “dressing” of the elevator. Which makes it a lot more efficient rather than having to change the entire elevator.

Different sizes and load ratings

There are different elevator frames to cover the different sizes. A BX frame 3, for instance, covers sizes from 9 5/8″ to 20″ casing, and a max load rating of 350 Short tons. A BX frame 4 covers sizes up to 9 5/8″, and load rating up to 500 Short tons. The BX frame 4 is used to run Tubing, Casing, DP etc. These are just two examples as there are other frames available which covers different size ranges and more load ratings.

Well, actually there is two different types of BX frame 4, BX4-50 and BX4-75. The BX4-75 can handle a load rating of 750 Short tons, but that is only when you are using special riser bushings for special operations. Otherwise it is also limited to 500 Short tons of load rating. This can also be relevant for other available BX frames.

> Read also: Tonne vs ton when measuring handling equipment weight

Versatility

In addition, the elevator can be fitted with either single rotator or a double rotator. The rotator attaches to the elevator and the elevator link (bail), and once operated the elevator will rotate. This means that you can easily pick up tubular from a horizontal position or easily close the elevator on a vertical hanging pipe. The elevator is closing automatically when the it hits the pipe.

Hydraulics

Since the elevator is hydraulically operated, you will of course, need hydraulics to connect it. If the top drive is not set up to run hydraulic elevator with all the controls needed (varies from rig to rig), you have two options. You can operate the elevator from a stand alone control panel using a hydraulic power pack. It is also possible to install a “BX operating kit” to most top drives to be able to fully utilize the efficiency of the elevator.

Topics: Casing Running

By: Arnt Joar Arnøy

Arnt Joar Arnoy has more than 25 years’ experience from the oil and gas industry. Holding positions as Workshop Mechanic, Service Technician offshore, Operation Engineer onshore. He is currently Operation Manager for OWS in Norway.