The importance of cleaning your BOP

Our mums taught us the importance of brushing and flushing our teeth. It is a routine job that saves us a lot of agony and expenses. But are we just as mindful of how we treat our blowout preventers?

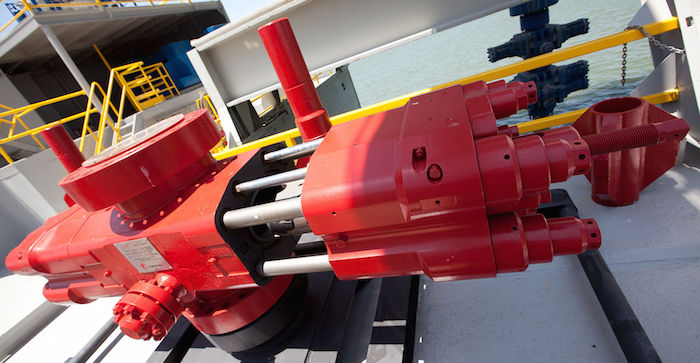

For anyone who wonders, the BOP (blowout preventer) is a giant piece of equipment sitting on top of the wellhead. It weighs several hundred tons and has one main mission: To shut in the well in case of an emergency.

Inside this machinery hides several annular preventers and rams, stacked on top of each other. When closed, they seal up the space inside the BOP in order to isolate the well below from pressure in the marine riser and to contain pressure inside the well.

A dirty BOP can cause these valves to malfunction, worst case resulting in a deadly blowout. You should therefore make sure that it is cleaned and tested regularly, as long as the BOP is in use.

How does a BOP get dirty?

Drilling through rock formations is a messy operation that produces a lot of cuttings. Rock debris is not the only type of cuttings though – by simply rotating the drill string you will produce fine metal debris, not to mention all the ferrous cuttings that is left in the annulus after milling or cutting the casing.

On it’s way out of the well and back to the surface (carried by the drilling mud) rock debris and metal junk has to pass through the BOP. Some of it stays there, hiding in the cavities of rams and annular preventers.

Why is a dirty BOP dangerous?

In particular, metal debris can be harmful to the BOP’s rams and annular preventers, since part of this equipment is made of rubber seals. When metal shavings accumulate around the rubber, it will over time be subject to abrasion. A leak annular preventer or ram equals a defect BOP. They will not be able to resist the enormous pressure that a blowout can create, and they will not be capable of stopping the sudden surge of hydrocarbons trying to force their way to the surface.

Take good care of your BOP

A healthy BOP should be cleaned of wellbore debris and junk every so often – especially in these scenarios:

- After milling and cutting the casing

- Before running the completion string (before production)

- As part of a plug and abandonment operation

- Before testing the BOP

Sometimes the BOP is pulled and cleaned manually – but it can also be cleaned while sitting on the wellhead. To obtain a proper cleaning of the BOP when it is connected to the wellhead, you will need proper BOP and riser cleaning equipment. What is important is that you manage to clear the cavities of sand, junk and debris that tend to hide there, but without forcing it further in to the BOP’s workings.

A wide range of wellbore cleanup tools is used in this process. A popular choice is a magnetized jetting tool that jets the BOP’s cavities, dislodging and capturing ferrous metal debris. This tool is often run in tandem with a junk catcher tool that collects debris that has been jetted from the BOP and the wellhead – dedicated magnets are often used in combination with these tools.

A clean BOP is a safe BOP. It should be tested and cleaned on a routine basis with efficient equipment that ensures reduced operating costs and a high quality cleaning operation.

[Photo: Ed Schipul – Flickr: Blow Out Preventer (The photo shows a typical BOP ram]

Topics: Wellbore CleanUp

By: Stephen Mair

Stephen has over a decade experience in WellBore CleanUp (WBCU) activities ranging from authoring industry best practices to WBCU research and development projects. With experience in various global locations (North Sea, Europe, Africa & Alaska) he has been involved in introducing the next generation of mechanical & software solutions to meet today’s WBCU challenges.