Shifting the Focus to Advanced Casing/Liner Deployment Technologies

In the current climate of lower oil prices, getting to total depth cheaper and faster is paramount. Companies are pushing the limits utilizing the latest drilling tools that drill faster; provide instantaneous corrections when steering; have more accurate logging; and overcome what was previously considered “un-drillable” wells.

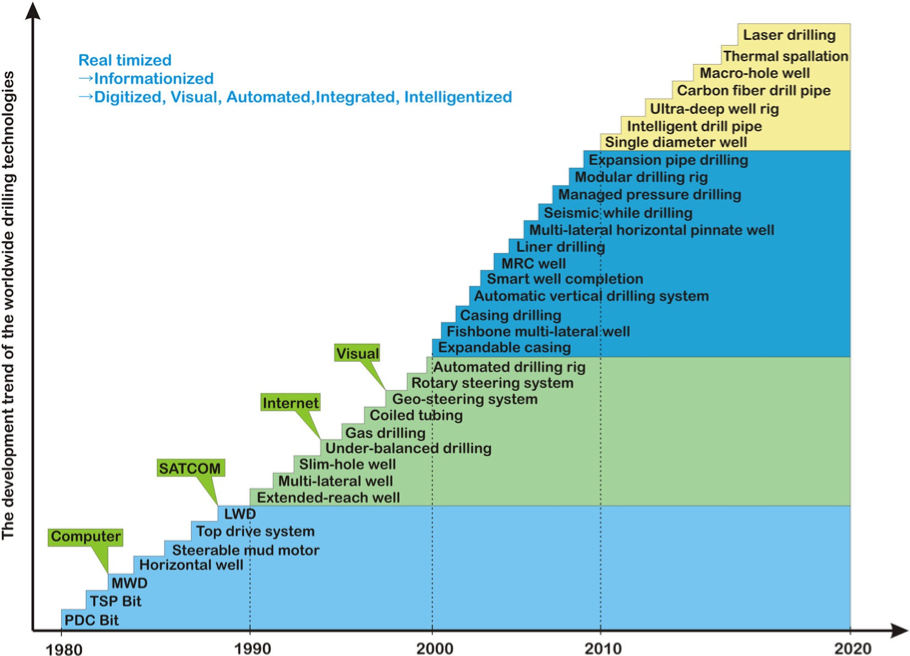

Besides drilling, the focus has been on the other stages of well construction. Yet very little investment and progress seem to have been made in technologies helping the casing to reach TD. So let’s look at some real data to highlight the status on casing running technological developments (see figure below).

The development of worldwide drilling techniques

Ma, T., Chen, P. & Zhao, J. Geomech. Geophys. Geo-energ. Geo-resour. (2016) 2: 365.

https://doi.org/10.1007/s40948-016-0038-y

As shown above, there’s been limited advancement when it comes to ensuring casing to get to TD in one run. The only new technology that involves getting the casing to the bottom is casing/liner drilling, which combines both drilling and casing operations at the same time.

So how to fill this gap in technological advancement?

Fortunately, there is already an answer to this question. Odfjell Well Services (& partner) provide Advanced Casing/Liner Deployment technology that is currently transforming casing running operations in the oil and gas industry.

The technology consists of a free rotating reamer hydraulically activated to provide high-speed rotation for effective reaming applications. It removes the need to rotate the entire casing string from the surface when reaming through problematic wellbores.

The OWS Advanced Casing/Liner Deployment system provides a fully developed and operational Defuse reamer tool with over 109 successful runs to date.

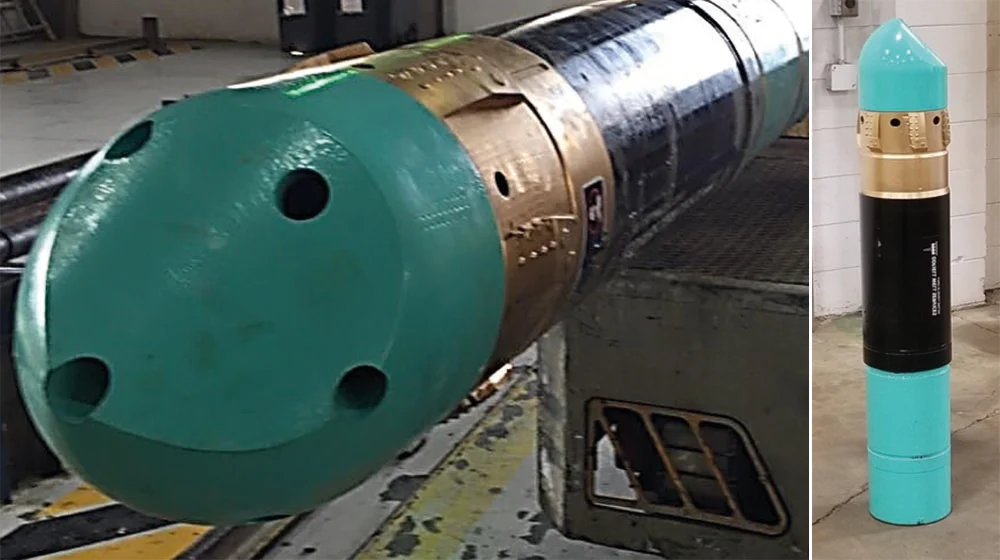

About the Defuse Reamer Tool

The Defuse high-speed reamer provides the versatility of a casing shoe that can rotate freely, passing over ledges in the wellbore without the aid of the pump. Once an obstruction is encountered, the pumps are applied to engage the drive mechanism inside the tool, transforming it into a high-speed reaming shoe. The tool enables the operator to circulate and ream through debris and ledges ahead of the casing, enabling casing to be landed on depth and on time.

When cementing, a more unified cement bond is now achieved around the casing, with the added advantage of a second shear; a result of the rotation of the Defuse reamer during the pumping process.

Once the cement has set, the Defuse reamer tool then becomes part of the wellbore construction and can be drilled out with the BHA of the next hole section. The internal assembly and the material of the Defuse reamer have been designed to be PDC/mill bit drillable. On average, the drill-out time with a PDC bit takes approximately 1 – 2 hours.

The Defuse reamer tool can either be supplied blank or cut to the desired threads on the box end of the top sub, to suit the client’s specific needs. Please see the typical image below.

The Defuse reamer tool has many other benefits when compared to the rigid conventional reamer shoe designs currently in the market.

Click on the video below to see the animation of the Defuse reamer tool in operation.

Other Defuse reamer tool features and benefits

- Rapid response when hole problems are encountered

- Variable tool speed can be controlled via pump flow rate

- Improved wellbore preparation before performing a cement job

- Added benefit to top drive casing running

- Can be manufactured in most of the casing or liner sizes

- The tool can be reworked to meet the desired RPM/flow rate outputs

- Designed for efficient drill-out with PDC bit

- High-speed bearings capable of >3000 RPM

- Customizable cutting structure and hard facing

- Available with or without integral float

- For high dog-leg applications with a risk of casing string fatigue failures, reaming operation can be performed without a need to rotate the casing string

How do I take advantage of this technology?

We would be glad to help you and be part of the solution to your hole challenges. Please drop us a message below or click on the email icon just below my photo to contact me directly.

To learn more about the Advanced Casing Deployment Technology products, please click here.

Topics: Drilling Equipment, Casing drilling

By: Derek Thomson

Derek has over 23 years experience, starting his oilfield career in the North Sea before joining Tesco’s casing drilling department in 2007. He joined Weatherford in 2014 as their Regional Casing While Drilling Manager for the Middle East and Sub Saharan Africa. Derek has vast experience with all aspects of Casing Drilling, including level 2 non-retrievable, level 3 retrievable, and directional liner drilling. In his 11 years working as a Casing Driller, he’s supervised 4 world-record casing drilling jobs and managed the world first directional liner drilling operation.