Riser Cleaning: Safe Operations, Boosting Efficiency and Safeguarding the Environment

By Ian Low, Product Line Manager – Wellbore Cleaning

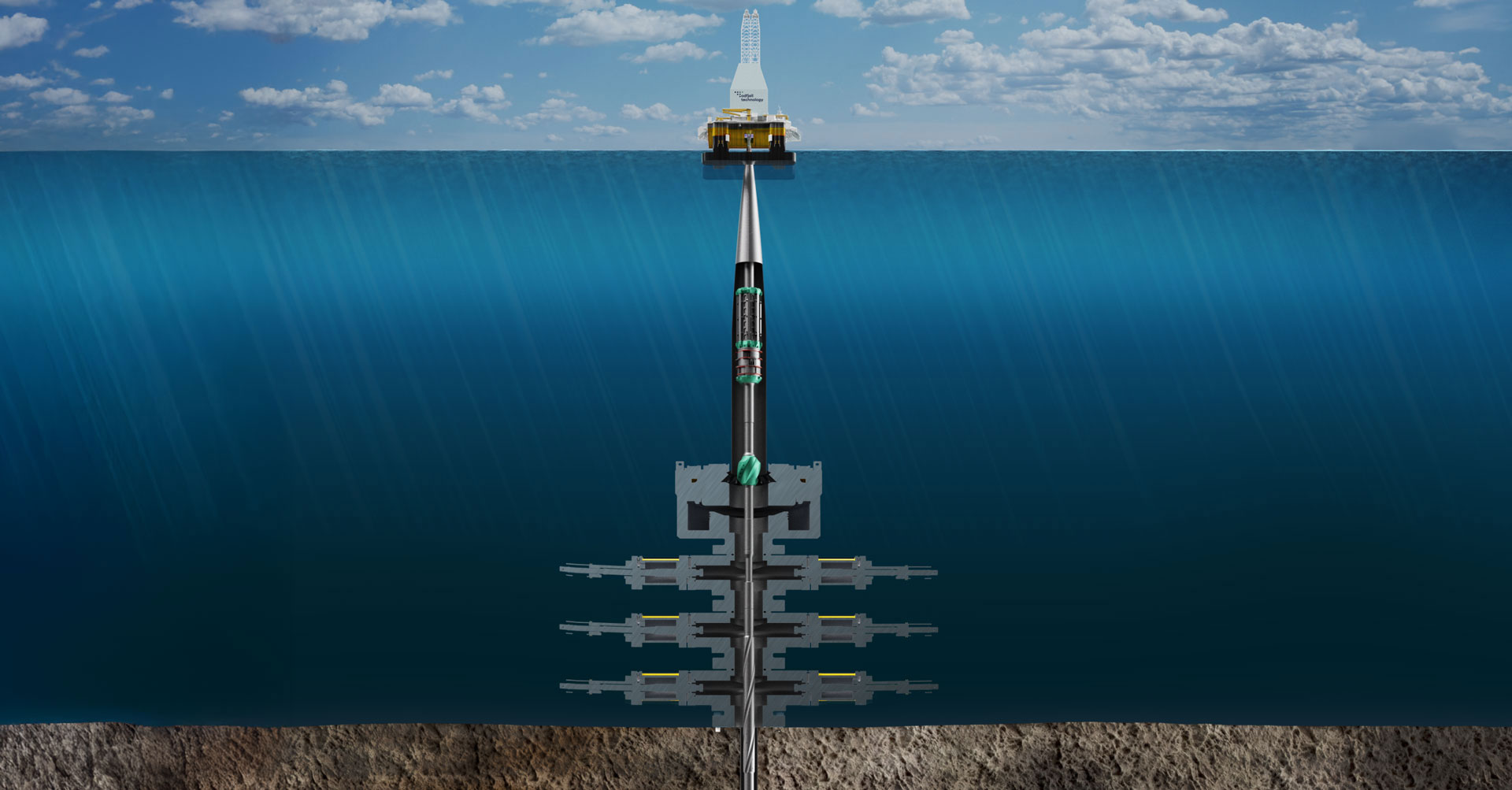

At Odfjell Technology, we understand the critical role of maintaining the highest standards for offshore equipment in ensuring the safety, efficiency and longevity of offshore operations. This is particularly true when it comes to the regular cleaning of risers and blowout preventers (BOPs).

While clients may sometimes prioritise the BOP over the riser, this presents an opportunity for us to highlight the importance of effective riser management. Our extensive global experience in riser and BOP cleaning allows us to provide comprehensive solutions that meet the diverse needs of offshore operations, ensuring optimal performance and safety.

Why clean the riser?

When disconnecting a riser from the BOP, it’s crucial to consider the possibility of debris, such as drill cuttings, residual mud or scale from the riser falling onto the BOP or seabed.

This debris can potentially interfere with the BOP’s functioning correctly, obstruct valves or control systems, and compromise well-control.

Additionally, the buildup of debris and contaminated fluids on the seabed can pose environmental risks to marine life, ecosystems, and future planned operations. Here is why regular cleaning is an absolute necessity:

- Compliance with regulatory requirements

Offshore drilling operations must follow regulatory standards to ensure safety and efficiency. These regulations are essential for preventing environmental hazards and maintaining the structural integrity of equipment. By adhering to these guidelines, companies can protect marine ecosystems and uphold industry best practices.

- Environmental

Maintaining a clean riser is not just about equipment performance. It’s about protecting our marine environment. Enhanced efficiency not only minimizes the risk of accidental release of harmful chemicals or debris into the water, but also contributes to a healthier marine environment and seabed, supporting future operations and marine life. By managing contaminants and debris directly in the riser, the risk of transporting them to the surface is minimised. This proactive approach reduces the need for additional handling and disposal, helping to mitigate potential environmental risks.

- Cost reductions

- Reduced Waste Management Costs: Cleaning the riser in place effectively minimises the amount of waste that needs to be managed, transported, and disposed of at the surface. This approach not only streamlines waste handling but also results in lower disposal costs, particularly for hazardous or specialised waste.

- Reduced Operational Costs: In situ cleaning of the riser offers a practical solution, often requiring fewer personnel and less equipment than surface-level cleaning operations. This effectively reduces the need for personnel, equipment and chemical costs.

- Increased lifespan of equipment: In situ cleaning is an effective method for preventing the buildup of debris and contaminants in the riser. This practice not only extends the lifespan of equipment but also lowers maintenance costs over time, leading to increased efficiency and reliability. Furthermore, when cleaned properly before storage —whether onshore or offshore — it significantly reduces the risk of corrosion.

Odfjell Technology can provide customised solutions to thoroughly clean your riser, wellhead and BOP.

These solutions are designed to maintain efficient operations, ensure safety, support compliance with environmental regulations, and promote sustainable offshore drilling practices. With Odfjell Technology, you can be confident that your equipment is in good hands.

Related Products

- MalstrømXT Wellhead & BOP Jetting

- Advanced Jetting Riser Displacement Sub

- Hydraflow Advanced Wellbore Cleaning System (HAWCS)

- RizeRdillo™ Riser Combi Tool

- UltraMag™ HD Casing Magnet

- XTractR™ BOP Junk Catcher

Built on heritage

With over 50 years of experience in well services, Odfjell Technology has a proven track record of delivering high-quality solutions for operators today.

As the energy sector continues to face new challenges, we continue to invest in and evolve our product offerings, emphasising efficiency, emissions reduction and flexibility.

Our cutting-edge technology and deep industry expertise position us as leaders in this rapidly changing and dynamic field.

You can read more about Odfjell Technology’s well intervention services in our wellbore clean-up blog here.

To discuss further, please get in touch with Ian Low, Product Line Manager – Wellbore Cleaning.