Identifying Casing / Tubing is imperative to safe casing running

This is probably the most important part of a casing crew’s job; identifying the pipe and ensuring all equipment and tools are within the specs to handle and make up the connections.

Why is this so important? The crew needs to understand what type of connections they are making up. Are they all the same, or are there different types in one string? This is crucial as torque figures might differ, connection OD and ID might change, or perhaps the connection is completely different and not compatible.

There are many ways to identify pipe and I shall try to outline how this process is done and what to look out for.

First priority

After the casing crew arrives on a rig, the main priority is to identify the type of tubular to be run. This will not always be as easy as it seems.

Casing could have been pulled out of the hole and ready to rerun, or casing has been within a company’s stock for years, and is hard to identify, due to rust and dirt.

Even though you should know how to identify the casing, your company should check beforehand with the client prior to doing the job, so you know what to expect when you arrive on site, thus giving you a chance to consult running guides etc. prior to arrival. You should obtain a detailed tally list from the client to ensure nothing is overlooked.

Identification

All pipe have stenciled information over the length of the tube which includes the weight (expressed in pound per foot), manufacturer, batch numbers etc.

The picture below shows typical information on the body of a casing joint.

In this example you can read :

9 5/8” 53.5 PPF VamTop Casing. The Casing Collar (box) is white, indicating P110 (grade of steel), which means this casing is of a harder steel.

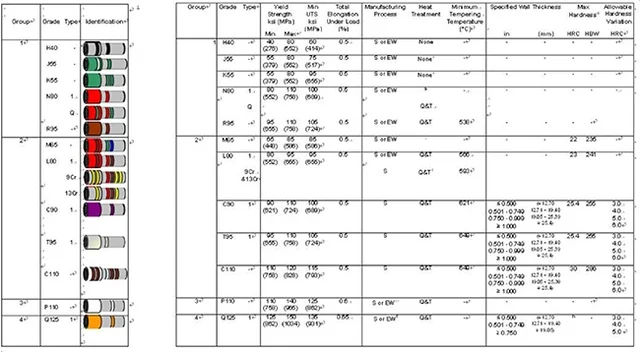

Also, the tubulars have color coding both on the tube itself and on the coupling. This is to determine the hardness of the steel, the certain grade i.e. sour service, high collapse, chrome etc

See below example of a color coding table (click picture for a larger version):

These are only a few examples of how pipe is graded and how to identify them.

Knowing how to identify the pipe, will increase the success of the job. It will ensure you have the correct tools, and importantly the right parameters, for making up the threaded connection and applying the set torque specified by the manufacturer.

Consult running guides

Once you have identified all specifications of the casing or tubing, you should consult your manufacturers running guides. These can be found online on their website or in small booklets that you carry to the rig. You might not always have a solid internet connection everywhere you go, therefore it is important to do your homework by sourcing as much information pre job as you can.

These running guides will give you more detailed information about the tubular & connection you will run. Through the specifications obtained from the pipe itself you can now find the following parameters:

- Casing make up values (Torque)

- Drift size

- Wall thickness

- Coupling OD

- Make up Loss

- Yield strength

- …..and the list goes on….

Next to all individual casing data, these manufacturers running guides will provide you detailed information on the particular connection, how to handle the pipe, how to apply running compound, what the make-up graph should look like and running speeds for the power tongs.

Especially when using a torque turn computer, it is imperative to fill out the right parameters in order to get the best results according to the manufacturers guidelines.

No guessing!

Never assume or guess when it comes to pipe identification! Double check all your data prior to the job!

As I outlined above, if you make up two different connections that are not compatible / interchangeable, then the the whole well is compromised. The connections don’t match causing leaks, or worse: If the connections have been over torqued (either pin or box) the ID is too small to let any downhole tools through.

The combination of basic know-how, careful planning and open dialogue with the client supports the necessary alertness to ensure a safe casing running process.

Topics: Casing Running, Casing Preparation

By: Hans Petter Moen

Hans Petter Moen has more than 30 years’ experience from the offshore / onshore oil & gas industry as Drilling Section Leader and Drilling Supervisor. He is currently Adviser Marketing, Technology & Operations at Odfjell Well Services.