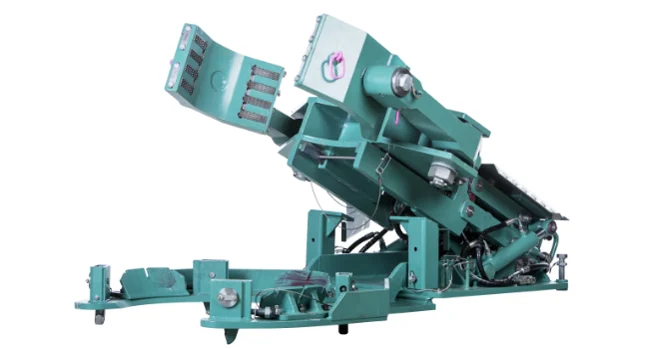

Efficient tubular running with automated slips lifter and safety clamp

Long sections of flush joint tubular require your crew to set slips and mount the safety clamp throughout the whole string. In completion, for example, when running a string of perforating guns, you might have as much as 300 – 400 connections including pulling. You could save a lot of backs while saving a lot of bucks, by letting the machines do the heavy work.

Flush joint casing or tubing

There are various flush tubulars; casing, tubing, perforating guns etc. They all require the use of a safety clamp at all times, on the whole string. By using a remotely operated slips lifter and safety clamp, the benefits of flush joint tubulars will be more available to you.

Completion string

When running a completion string you always have to take precautions to arrange the cables in a manner that prevents them from being squeezed between the slips and the OD of the tubular. When running completion lines with insert bowl #3 with groove, the automated slips lifter takes care of your cables so they run freely in the groove.

Save backs

The nature of remote operation is to separate the operator from the operation. The automated slips lifter and safety clamp may be operated from a stand-alone remote hydraulic control, or a wireless control panel. The wireless control panel is usually used from the drillers cabin. When you’re planning your project and making the calculations, you should give a minute of thought to the following scenario: Drill floor personnel having to mount and dismount the safety clamp, and lift and lower the slips, several hundred times during a run. Then ask HSE if back injuries are a fundamental reason for sick leaves. After that you may have a broader perspective of what the right choice of equipment is.

See also: The correct use of safety clamps

Save bucks

A run with a perforating gun would often reach 300 – 400 connections including pulling. Mounting the safety clamp manually will typically take 2 minutes. Doing it remotely takes maybe 30 seconds. That’s up to ten hours saved! Add to that another 30 seconds gained on dismounting the safety clamp and you have another 3,3 hours saved. Up for more savings? The amount of people needed to operate the safety clamp is reduced from four (on the large casings) to one. This might be just what you need to ensure that flush joint tubular is used when it’s the best solution for the job.

Topics: Casing Running

By: Arnt Joar Arnøy

Arnt Joar Arnoy has more than 25 years’ experience from the oil and gas industry. Holding positions as Workshop Mechanic, Service Technician offshore, Operation Engineer onshore. He is currently Operation Manager for OWS in Norway.