Drilling thread types for dummies

At Odfjell Well Services we constantly hear from people who ask us why certain drill pipes don’t go together. Sometimes these are experienced drillers who have been in the industry for years. So here comes a post with the need-to-know basic stuff about drilling connection types. Hopefully it will be of use to you – whether you’re a rookie or a veteran.

What kind of thread types are we talking about?

It can be tough getting the terminology right, so let’s nail it down right now. In this post I will deal with the drill string connections only. I won’t be talking about connections for casing or tubing.

To narrow it down further we are going to look at Rotary Shouldered Connections (RSC). RSC’s come in two sub-categories:

- API connections (American Petroleum Institute)

- Premium connections

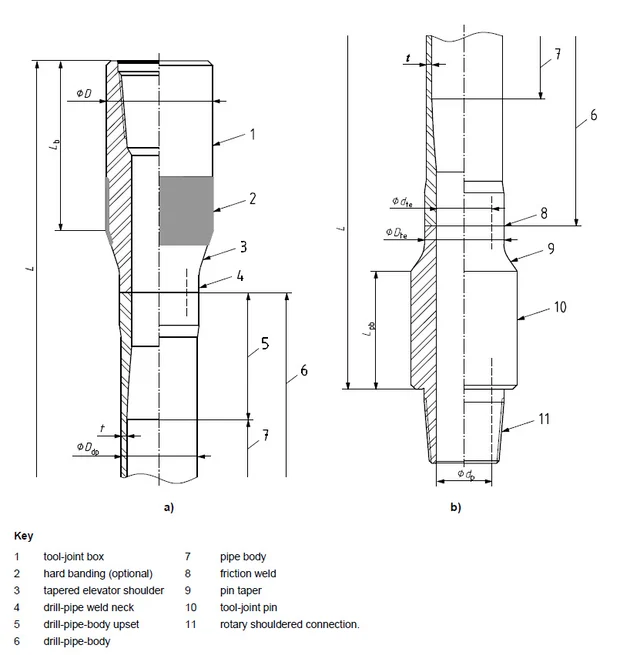

Study the schematic for drill pipe tool joints below to gain a better understanding of what we are talking about:

> Read also: How to choose the right drill pipe

API Connections

API connections go under many names:

- Regular

- IF (Internal Flush)

- FH (Full Hole)

- NC (Numeric Connection).

These are single shoulder connections: They only have one torque shoulder on both pin and box.

Premium connections

Premium connections are like cell phone chargers. They come in different shapes and sizes from the many competing factories. Some examples are:

- XT (Grant Prideco),

- DSTJ (Tenaris)

- Vam Eis (Vam)

- MT (DP Master).

Most premium connections have a double shoulder. That means that they have an extra torque shoulder in the nose of the pin and in the bottom of the box. This provides a bigger shoulder area, thus allowing a higher makeup torque.

Designed with drilling in mind

As is common for all threaded connection types, RSC’s are designed with a single purpose in mind, namely drilling. They must be strong enough to endure different loads and combinations of tension and torsion.

What might come as a surprise to many is that no API RSC is pressure rated with regards to gases and liquids. The drill string data sheets tell us what the pipe can endure internally in the drill string before it bursts or collapses. Yet, this applies to the pipe, and NOT to the connections.

RSC’s can endure high pressures under favourable conditions. But take the necessary precautions. You don’t want an unexpected shoulder separation and an uncontrollable leak when drilling a deviated well..

Why all these connections?

But why all these connection types? Why can’t we as an industry just pick the best one and go with it? That is a legitimate question. The short answer is competition. Manufacturers compete for the best connection, and that will probably continue for some time.

Compatibility

The wide range of connections naturally brings up the question about compatibility. Can we screw type A together with type B, etc.? Yes, some connections go together with other types under given circumstances. Let’s take a look at how this works.

Premium + API

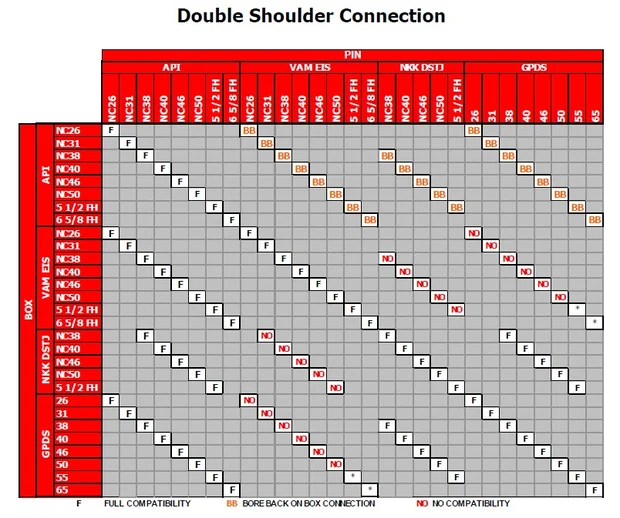

Some premium connections are compatible with API connections, even though one of them has a double shoulder and the other not. These premium connections have the same thread profile as the corresponding API connections. Examples of this are Vam Eis, DSTJ, GPDS, etc.

If there is space enough for a secondary shoulder in the API box, this can be a solution. In these scenarios the API box typically has a bore back (BB).

Before you try to screw different connections together, do the following. Ask your drilling equipment provider whether they permit it. If they do, take care to use the makeup torque values for the weakest connection.

Premium + Premium

Only in rare circumstances can you screw together two different types of premium connections . In order for this to work the thread profiles need to match each other. Besides, the dimensions (diameter and length) of the secondary shoulder need to allow it.

Feel free to use this compatibility matrix as a guide when trying to figure out what goes together with what:

So until a genius invents the perfect quick connection, we just have to accept the status quo and live with it. As Voltaire so eloquently put it: “One day everything will be well, that is our hope. Everything’s fine today, that is our illusion”.

Topics: Drilling Equipment

By: Frode Bjørheim

Frode Bjørheim is a specialist in drill pipe standards and lifting equipments with more than 30 years’ experience in the oil & gas industry, both offshore and onshore.