Casing Make-Up Torque and Turn

If you think make-up is all about reading graphs on a computer display, this is undoubtedly a blog post you should read carefully.

To master the art of applying correct make up torque and turn you need to master quite a few other skills. In the following I will outline the most important aspects influencing the make up.

1. Identifying the pipe

A TRS specialist should be able to determine a lot concerning casing make-up just by visually inspecting the tubulars stacked on the pipe deck.

- Are the connections of the same type? If grades/weights are variable, the compatibility should be verified with the manufacturer.

- Special attention should be given to a visual thread inspection to both box & pin ends to ensure no damaged joints shall be run into the well.

- Further more the OD & ID should be measured, and coupling type and any internal or external upsets should be noted.

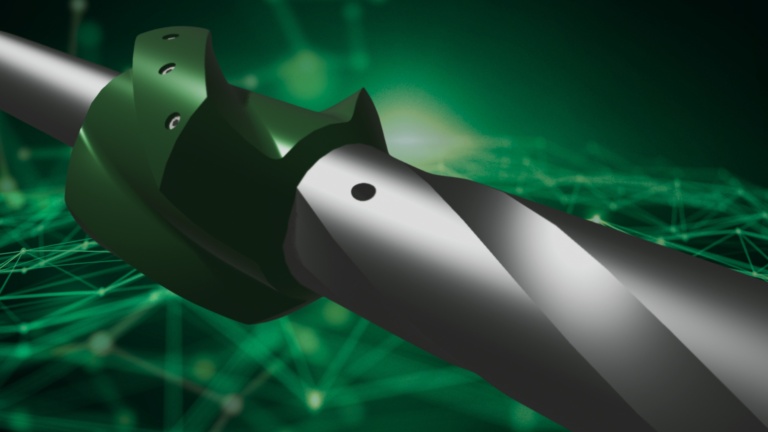

2. API or Premium connections?

A premium connection derives its primary pressure sealing capabilities by the use of at least one metal-to-metal seal. This design makes the connection stronger, and higher torques can be achieved whilst a gas tight connection is assured. These connections will typically be made up with the use of a torque turn computer in order to plot the make-up graphs.

Depending of the type of connection, some customers would prefer to run without computers to obtain certain running speeds. Typically, API-connections will not generate a proper make up graph. You will be able to monitor the torque however, despite no clear evidence of an integral make up.

3. Select the right power tong- and torque turn monitoring system

Selecting the correct tong for the job is critical. For instance, a 14″ power tong with a torque output of 40K Ft/Lbs. is too heavy for 4 1/2″ tubing with a make-up torque of only 2,500 Ft/Lbs.

Do we choose computers or torque gauges? The type of tubular being run should determine the monitoring system, and selection of the system should be agreed with the client prior to commencing the job

4. Dos and don’ts regarding power tong handling

- Adhere to manufacturers recommendations, data sheets and running procedures.

- Each connection needs to be visually inspected prior to running through the rotary table.

- Avoid “jerking” on the operating levers, which can result in pipe damage.

- The running speed of the tong must be in accordance with the manufacturers recommendations.

- All “measuring” devices must be calibrated and within spec.

- Make sure all safety features on the tong are in good working order.

- Discuss the safe use of Hydraulic Power Tongs in the Toolbox meeting on the rig floor.

5. Correct thread compound application

This is extremely important for obtaining good make up graphs.

Make sure you use the correct thread compound, and prevent contamination. Evenly distribute the compound onto the tubular threads in accordance with the manufacturers running guidelines.

6. Making and breaking out the connections

Programming the computer with the correct parameters is key to success. If you get the parameters wrong, it could have disastrous consequences to the integrity of the connections being made up.

The correct parameters are vital for the rest of the operation. Make sure you get them right from the start.

7. Graphs, identification, interpretation

In order to understand a make-up graph, we have to understand the geometry and properties of the connection we are making up. A Torque Turn Specialist will be able to distinguish three different characters in a graph: thread interference, thread and seal interference and shoulder torque with a clearly identified stop-shoulder point. Carefully observe the delta turns applied onto the shoulder to determine any plastic deformation or yielding.

Within the acceptance criteria the following parameters should be monitored:

- Maximum, minimum and optimum torque.

- Minimum and maximum shoulder torque (the shoulder point should be within this window).

Any tubular make up that is doubtful should be broken out, inspected and laid down if rejected.

Skills never go out of fashion

Even though the make up torque and turn can be considered a small piece in the casing puzzle, it requires a deep understanding of the gear and the process of casing running.

The clear message is that the craft is based on knowledge and experience. Considering all the factors that must be looked into and mastered to correctly apply make up torque and turn, there is never an alternative to hiring an experienced crew of TRS experts to run your casing.

Topics: Casing Running, Casing Preparation

By: Robert Koendering

Robert has 15 years experience in tubular running services which comprises pile driving, running casing & high chrome completions, bucking & pressure testing. He is an expert on top drive casing running tools & DwC operations (Level 2).